Void Fill Solutions

Delivering on Proper Packaging Protection

End-users expect product to arrive on time and undamaged. At Colony we often see an overuse or underuse of material when it comes to “filling the void”. It’s easy to get into the right product combination that makes sense to your operation whether your packaging into a box or shipping FTL pallets of material.

Cushioning

The first step in protecting a shipment is cushioning a widget with enough material to prevent damage while in transit. This can include paper cushion wrapping, bubble wrap, or die-cut options like honeycomb or various foams. An item should always first be fully cushioned with about 2” worth of material before any type of void fill is added to the package. It is recommended

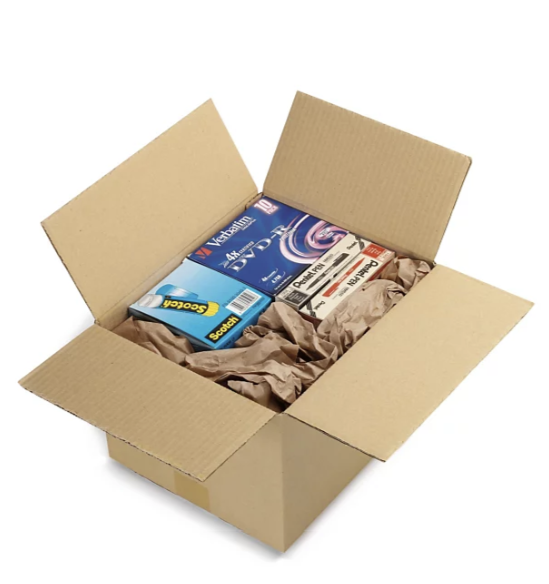

Void Fill

Used when an item is already protected but the box has extra space which needs to be filled. Void fill prevents items from shifting while shipping to decrease risk of damage. Oftentimes companies sending mixed shipments can benefit from additional on-demand void fill as the “voided” space is variable and packers need easy and in-line options to meet production line speeds.

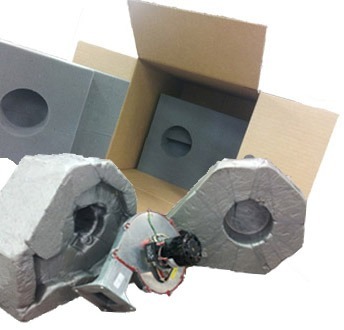

Blocking And Bracing

A form of securing standardized packages which prevents shifting within the box. Blocking and bracing techniques can include using corner protectors, on-demand pads or die-cut pieces. This option is ideal for shipments that have non-variable configurations for a reliable “kitting” experience to decrease chance of damage.